Monthly Archives: July 2019

How Wimbledon and Watson use AI to edit autofocus for video (Part 1)

Audiences will surely remember the breathtaking tennis final between Novak Djokovik and Roger Federer at Wimbledon 2019 on July 14th. Wimbledon tennis championship is one of the most prestigious sporting events in the world. Wimbledon is also the oldest tennis tournament in the world when it was first organized in 1877.

Many things have changed in the last 142 years – from players’ costumes to the quality of their accompanying items. However, behind it is a continuous development of artificial intelligence technology, which has been changing the way images are captured and edited for the public.

Wimbledon has all 18 grass fields. It is also the venue for nearly 700 matches in a two-week period, including men’s singles, women’s singles, men’s doubles, women’s doubles and women’s matches and many more forms of competition. Six main matches, holding matches attract the most attention, there are an average of about four matches a day. Last year, for the first time, all activities in 18 stadiums were broadcasted online, using a combination of cameras with operators and robots. Therefore, developments in the yard are provided to viewers with unprecedented numbers as before. However, it also created a lot of scenes, too much to screen information in time. This is where IBM believes automation can work.

IBM has worked with Wimbledon organizers at All England Lawn Tennis & Croquet Club (AELTC) for three decades. This unit is in charge of information technology, network security and all digital assets serving customers, including applications and websites, where fans update developments.

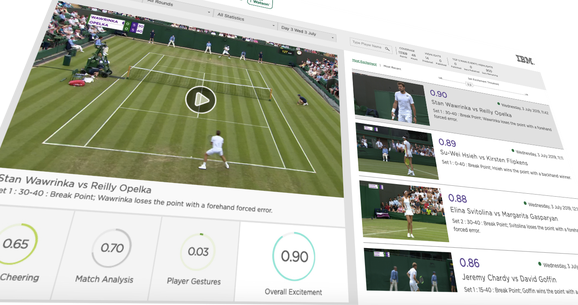

In the past six years, IBM has applied AI Watson’s intelligence in many ways, but IBM recently increased its use of Watson in Wimbledon. Here, Watson helped capture all the best bits of data in each match and packed them in a two-minute highlight at the end of the game, updating the section that was thought to cause the most labor-intensive.

Simon Boyden, chief architect at IBM, said in a briefing: “We are doing the job in a traditional way that will cost a lot of manpower, expenses and time, from which to support in making match points as quickly as possible. ”

Technologies make Formula 1 the safest race in the world

Biometric gloves, helmets withstand impact force of up to 20 tons and high temperature up to 800ºC, halo protects life even when a 2-floor bus falls … The most advanced technology and stringent regulations have turned seemingly unsafe F1 racing cars into utopian safety on every journey.

Formula 1 cars (F1) travel at an average speed of 250-300km / h. Each corner creates a fierce competition between 24 riders and always poses a threat to the lives of people in the car. Technology applications have solved that problem – making racing cars safer than ever.

The hat “accepts” all bumps and temperatures

Each driver is required to wear protective clothing to withstand high temperatures and fire during driving.

The first part of the driver’s face is protected by a helmet made of metamaterials. The hat must pass the tests of FIA (World Motor Vehicle Federation) such as: withstand impact force up to 20 tons, withstand temperatures up to 800ºC, withstand the impact of a Long and heavy steel bars fall freely at a height of over 5 meters … In return, the cost to complete each hat is usually up to over USD 9,000.

HANS – “talisman” of the lumbar vertebrae

Seat belts with HANS technology are one of the talismans of F1 riders

At speeds above 250km / hour, if crashing into a retaining wall, the driver’s neck will suffer a great force, a spinal fracture and it is difficult to preserve life.

Each rider when sitting in the cockpit will have to wear up to 5 protective straps containing the external force suppression technology: 2 shoulder cross wires, 1 rope around the abdomen, 2 wires on the legs. The foot / knee part of the driver is also designed with dynamic damping pads to avoid injury in the event of a collision.

In 1980, two biologists, Jim Downing and Bob Hubard, invented HANS, a device designed so that when a collision occurs, elastic belts absorb and destroy almost all forces. slide down the protective belt over the shoulder of the driver. HANS helps to reduce over 65% of the impact on the head, nearly 90% of the impact on the driver in any case – minimizing possible injuries.